Aerospace & Defence

AI-Enabled Quality Assurance & Compliance for Aerospace & Defence

100% indigenous and 3Frames proprietary solutions for seamless command and control.

Built to address the precision and superior quality & compliance standards of the aerospace and defence industry.

Quality360 is designed to meet the aerospace and defense industry’s stringent standards for precision and quality. As the industry experiences a surge in demand, challenges like supply chain complexities, shortage of expertise, and the need for rapid digital transformation become more pressing.

Quality360 is a comprehensive solution that enhances the efficiency of quality control in a rapidly evolving industry.

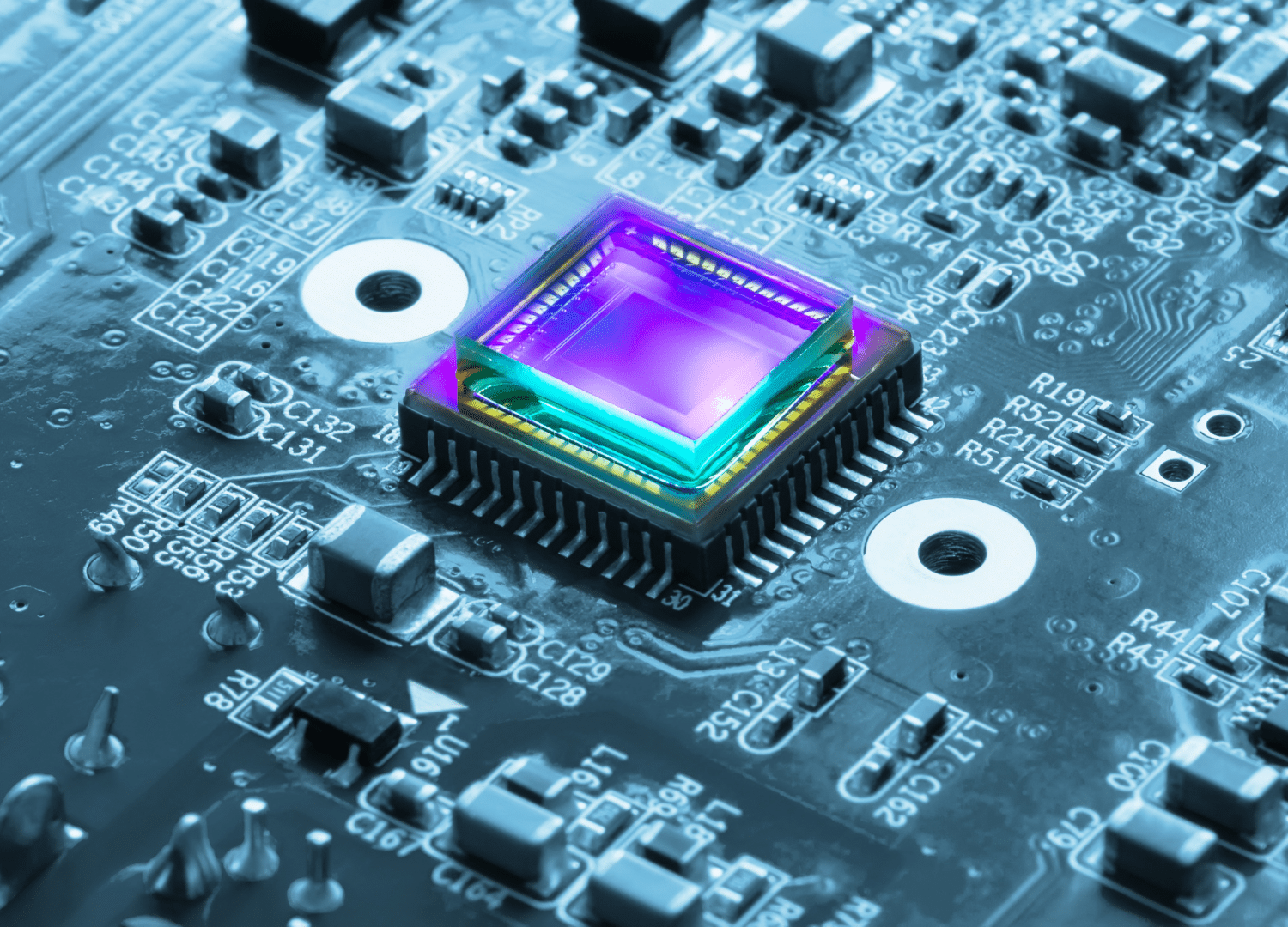

Computer Vision Enabled PCB Inspections.

Quality360 helps drastically cut down the time and effort spent on identification of defects and issues on all types of Printed Circuit Boards (PCB).

Indigenous Thermal Cameras

Advanced thermal imaging to monitor and analyse anomalies in real-time.

Indigenous Inference Engine

Analyse and decide faster with an advanced inference engine.

Deep Learning-led Automated Quality Inspections and Tracking

Detect and analyse defects at the source through computer vision and sensor fusion.

Intelligent Edge Driven PCB verification

Identify the smallest of defects with thermal imaging and increase productivity.

Aircraft & Missile Maintenance Checks.

Use indigenously built thermal cameras and AI predictive analytics algorithm to efficiently track and fix defects and anomalies.

Automated Surface Inspections and Tracking

Visual inspections and tracking of surfaces, exhaust and hydraulics.

Automated Visual Inspections of Parts

Identify missing parts, parts with wrong orientation and dimensions, and sequencing during assembly.

Real-time monitoring of Missile Assembly and Sub-assembly

Keep track of every aspect of the missile assembly through production and storage through real-time monitoring of every aspect of the process, across suppliers.

Comprehensive Safety and Compliance Monitoring.

Align and track every aspect of regulatory and safety compliances easily in one tool.

Automation that enables 100% OSHA compliance

Automation and tracking of essential parameters to ensure 100% compliance at all times.

Monitor, track and verify process adherence

Make process mapping and monitoring simpler through advanced thermal imaging and AI.

One dashboard for Quality, Safety and Compliance

Bring all elements of safety and compliance on to a single platform.

State-of-the-art AI and Machine Learning Features.

Equipped with cutting-edge AI, computer vision, and automation technology Quality360 offers truly 360-degree quality automation and digitization features.

Material Test Certificate (MTC) Automation

An advanced OCR system scans material test certificates (MTC) with precision. Coupled with AI, it maps data to specific aerospace standards, ensuring all materials, from raw material to finished product meet industry demands.

Connect QA Labs Seamlessly

Ensure real-time data exchange and seamless connection across QA labs to guarantee that every component, from avionics to propulsion, meets the stringent industry standards.

Raw Material Inspection and Testing

Trace back, track and monitor every inspection to ensure each material aligns with rigorous aerospace test specification codes.